Scope of Work

.01/

Legacy Code Modernisation

.02/

UI/UX Redesign

.03/

Frontend Development

.04/

Backend Development

Creative Idea & Execution

.01/

Revamping the Legacy

- Transitioned the system from a dated tech stack to a robust, scalable architecture capable of supporting modern manufacturing processes.

- Designed the system to align with Industry 4.0 principles, incorporating real-time data tracking, analytics, and remote accessibility.

.02/

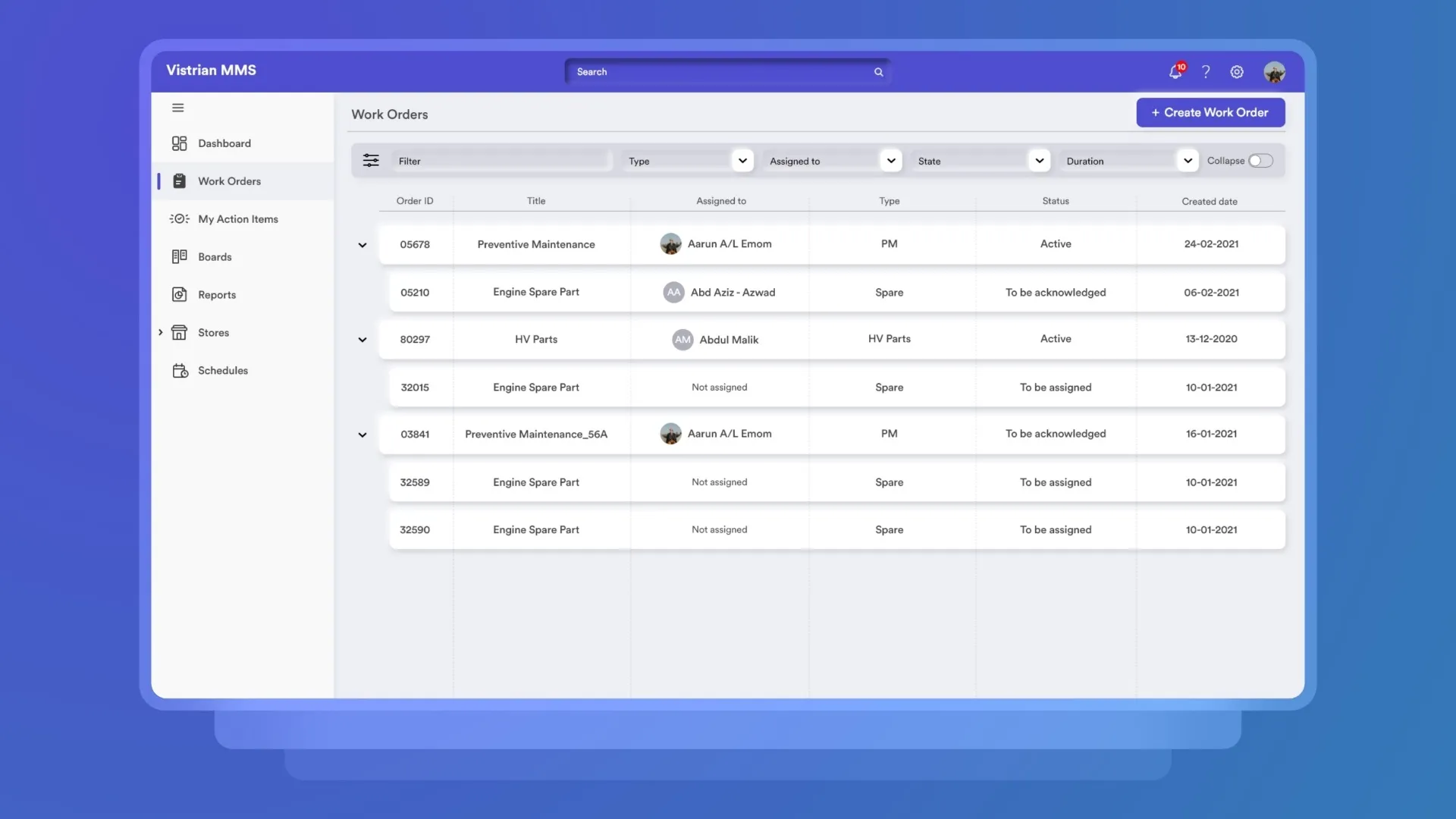

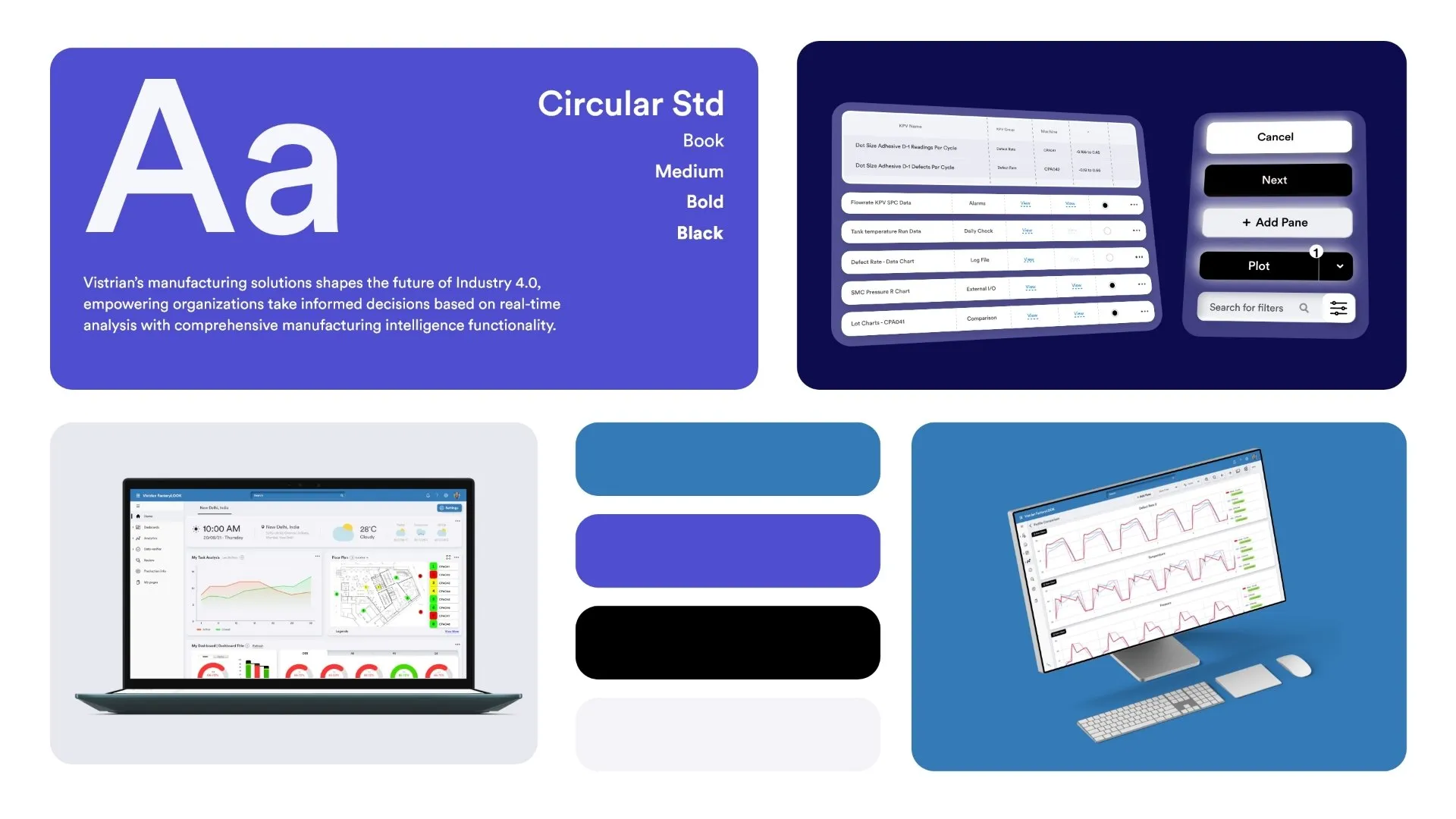

Modern UI/UX

- Delivered a clean, intuitive design using React.js, ensuring a seamless experience for factory operators and managers.

- Focused on simplifying navigation and improving usability for diverse user profiles.

.03/

Code Overhaul

- Updated and optimised legacy backend logic with C#, ensuring compatibility with new workflows.

- Leveraged MSSQL to enhance database performance and support complex queries for manufacturing analytics.

.04/

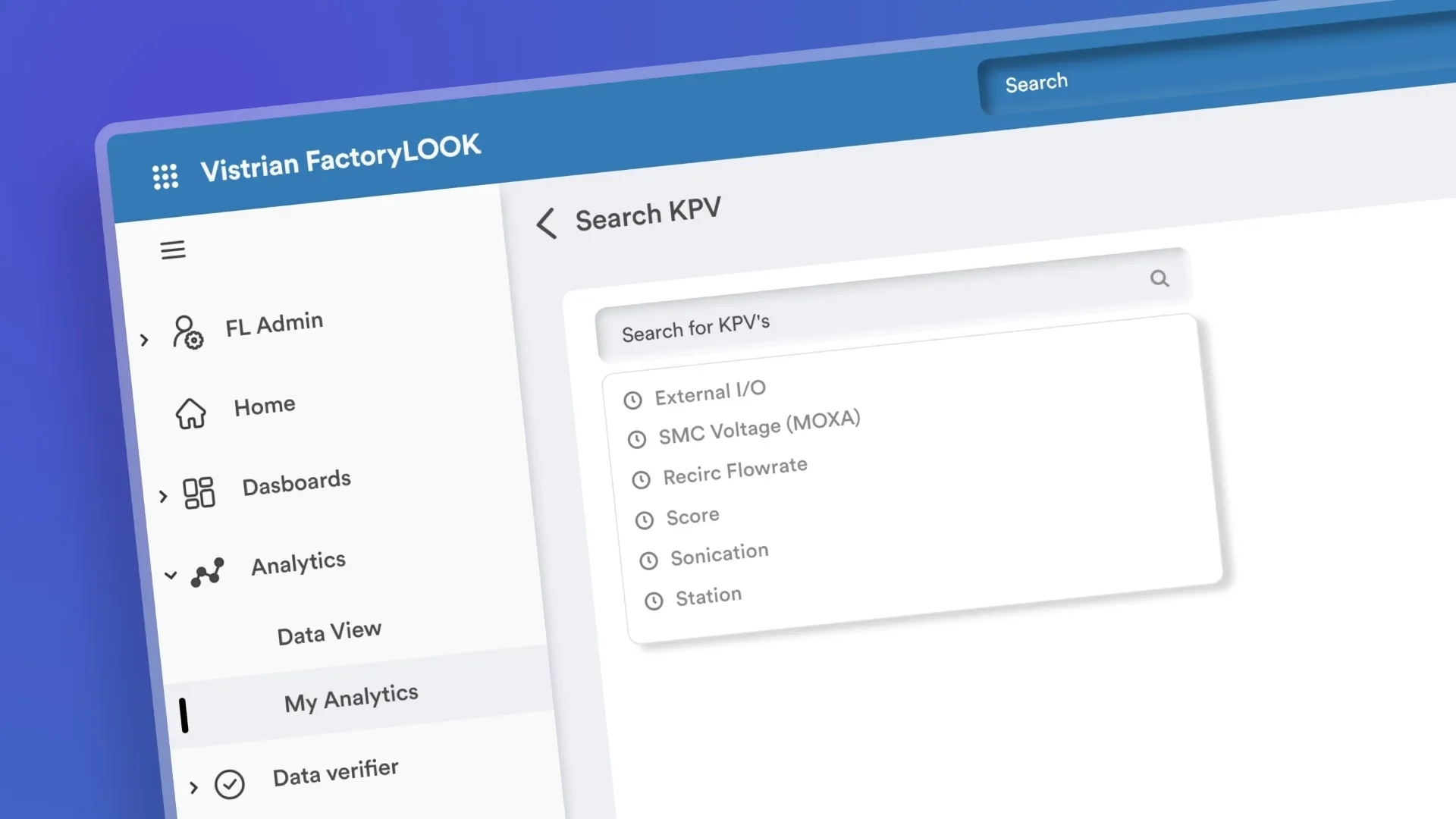

Industry 4.0 Features

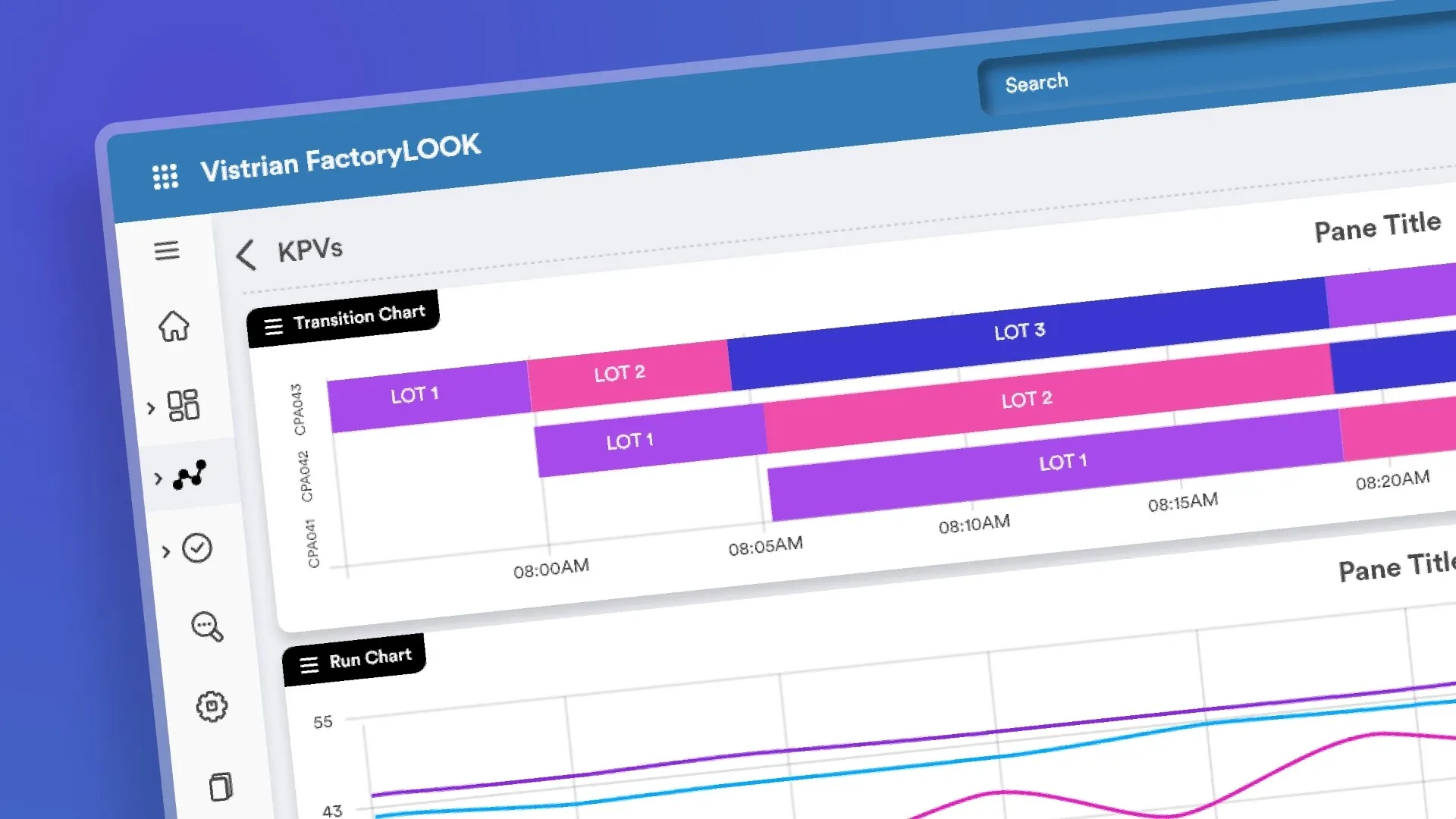

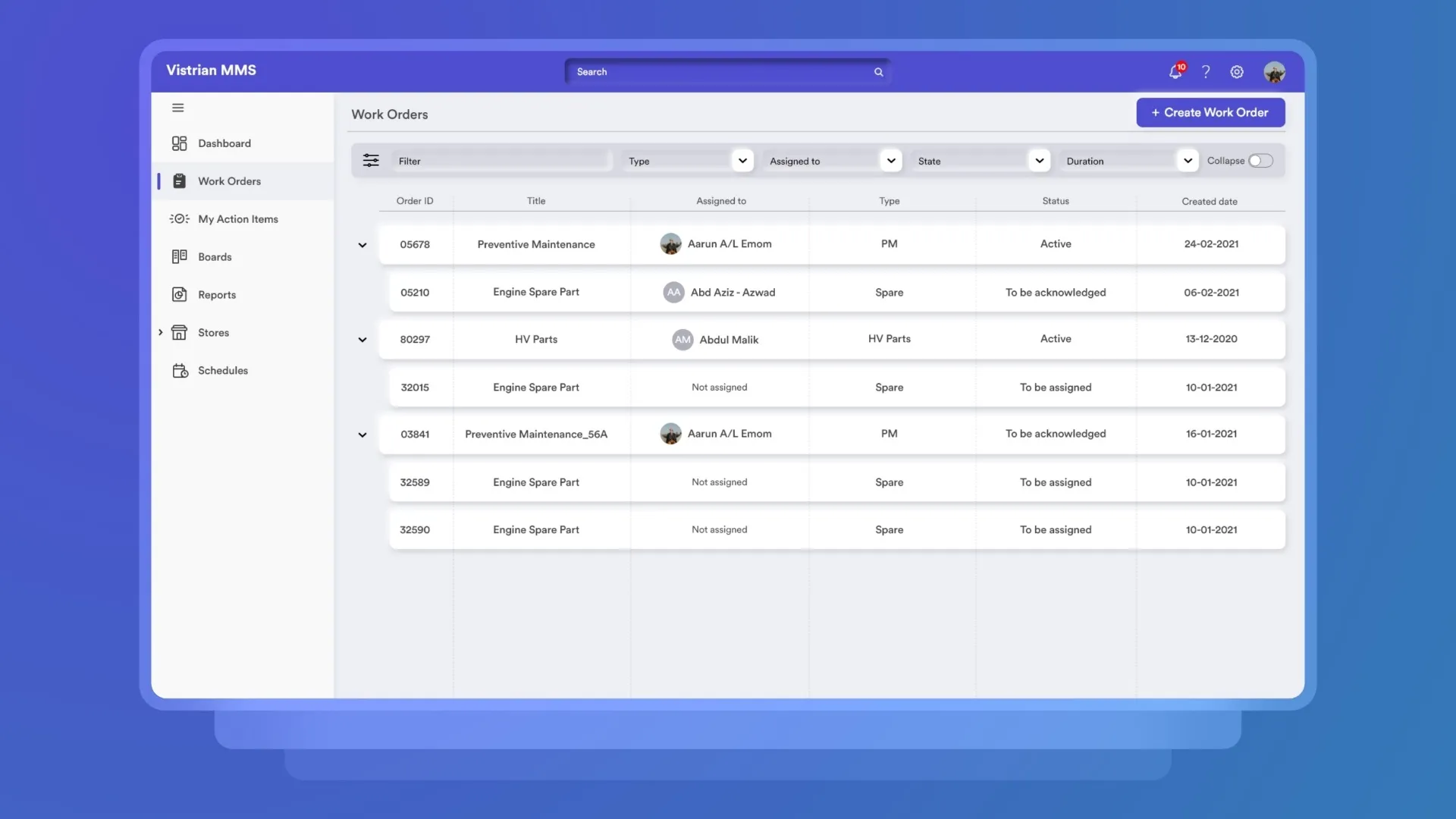

- Integrated smart monitoring, predictive maintenance, and IoT device connectivity to enable data-driven decision-making.

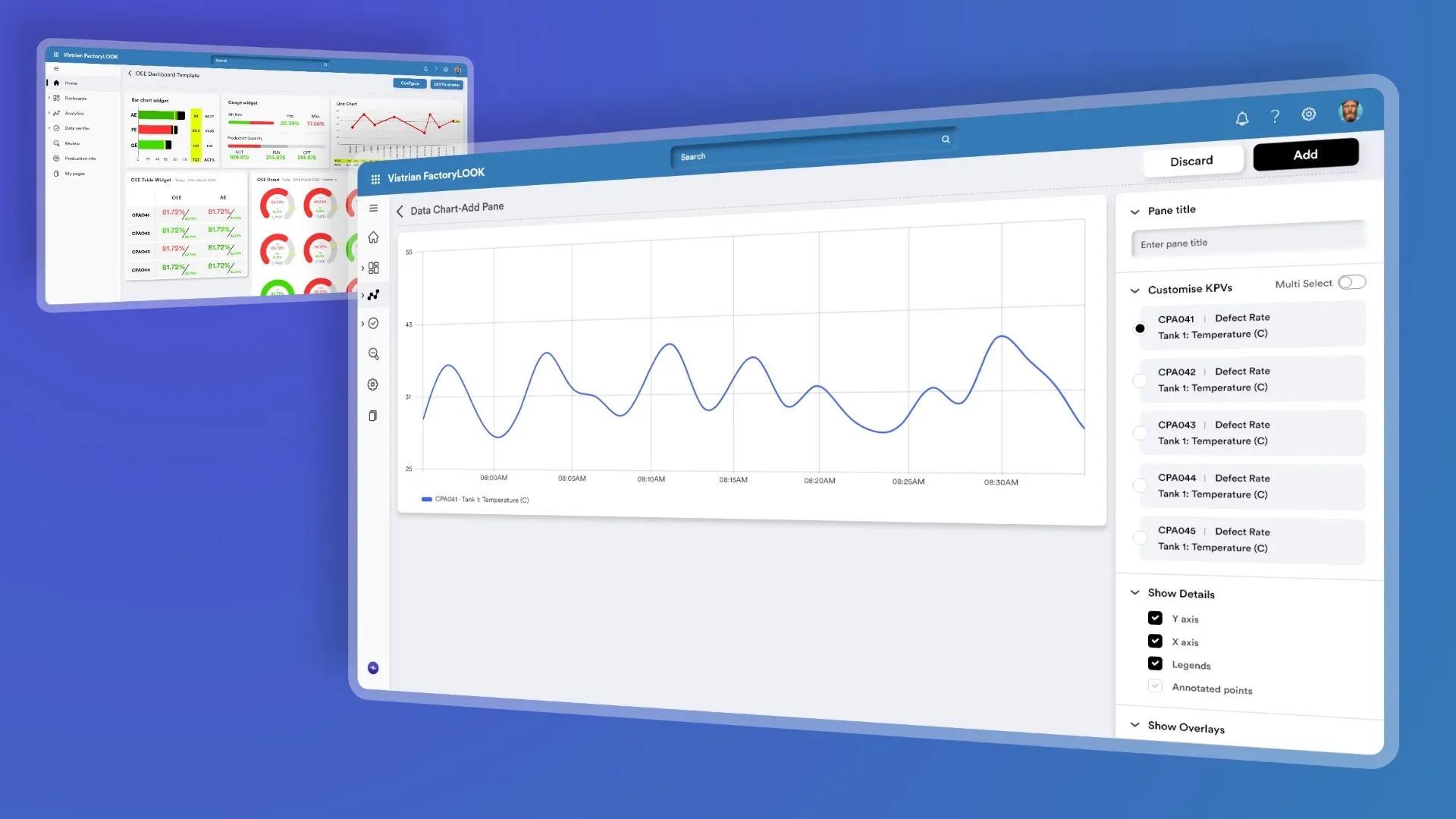

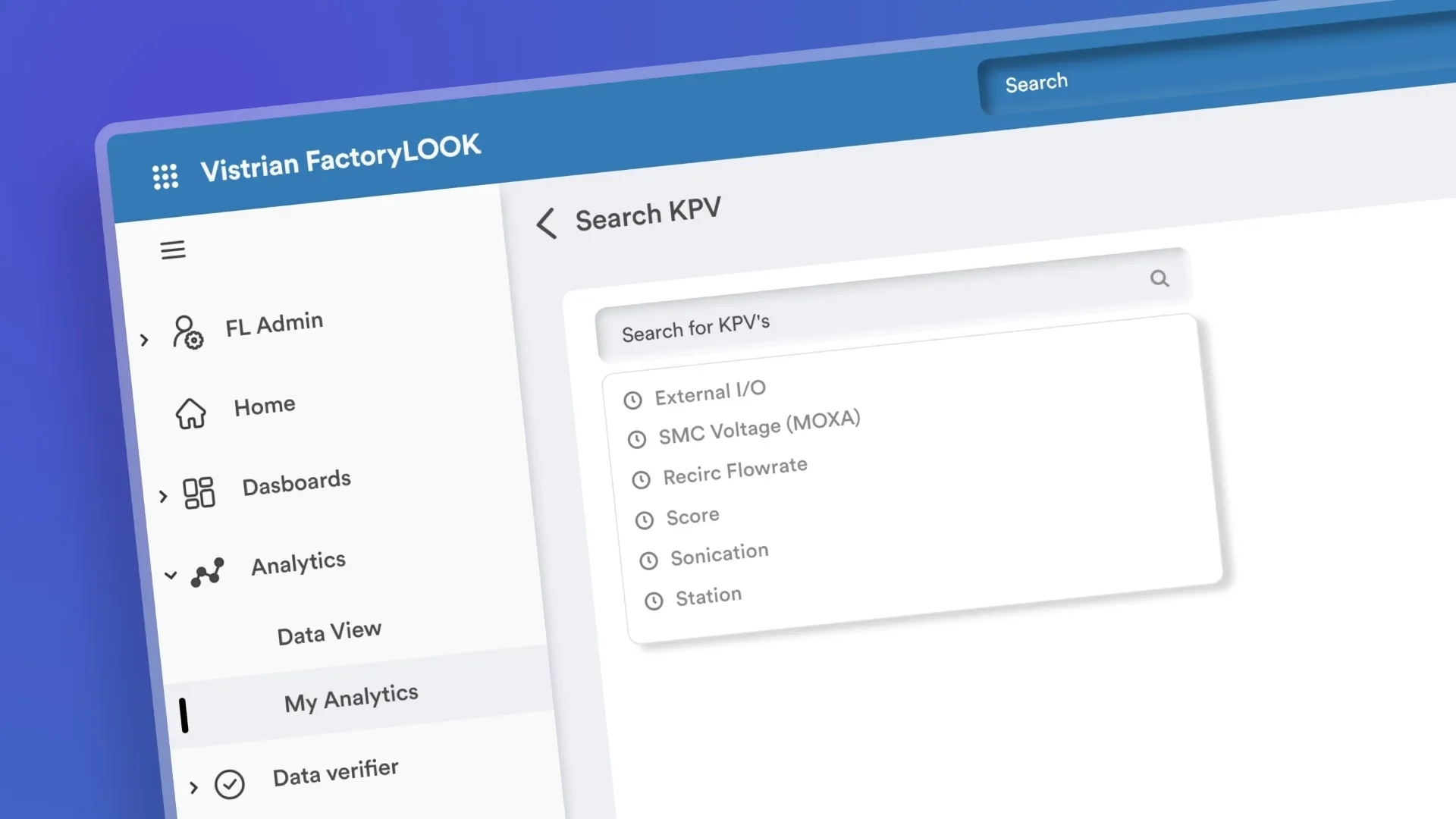

- Designed custom dashboards for real-time KPI tracking, anomaly detection, and performance optimisation.

- Customizable User-Defined Dashboard with Interactive Widgets.

- Redesigned and Developed Equipment Tracking Software.

Results of the project

Future-Proof Solution

Successfully modernised a 20+ year-old platform, aligning it with Industry 4.0 standards.

Improved Performance

Enhanced system speed, reliability, and scalability to support complex manufacturing workflows.

User-Friendly Interface

Intuitive web-based UI simplified adoption and improved productivity across teams.

Seamless Transition

Achieved a smooth migration from legacy systems without disrupting ongoing manufacturing operations.