We build Human

Experiences for the

Digital world

Integrating technology & creativity to meet

all your business needs.

THINK

DIGITAL

A partner who got it all

Our Solutions

Branding

Flexing your brand's full potential

Make your brand stand out with a complete design solution at your disposal, helping you increase brand recognition and recall.

Brand Strategy ![]() Brand Identity

Brand Identity ![]() Communication Design

Communication Design

![]() Brand Strategy

Brand Strategy

![]() Brand Identity

Brand Identity

![]() Communication Design

Communication Design

Leading Companies

Branding

Marketing

Marketing

On-point marketing solutions

Master the digital space with our incisive marketing strategies, social media management and winning influencer campaigns.

Website Building

![]()

Social Media Marketing

![]() Ad Campaigns

Ad Campaigns

![]() Website Building

Website Building

![]() Social Media Marketing

Social Media Marketing

![]() Ad Campaigns

Ad Campaigns

Leading Companies

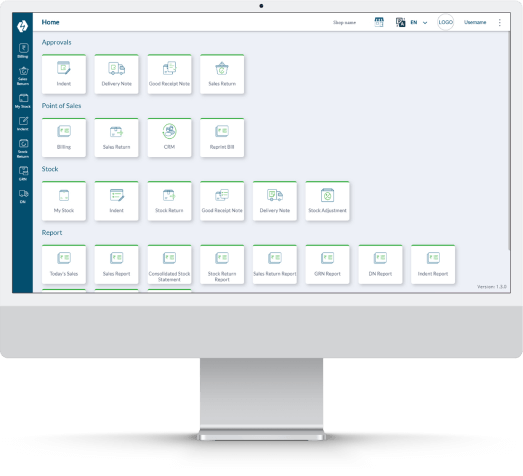

Product Development

Watch your ideas come to life

Build your next digital product with a complete product development team, guiding you towards realising the full potential of your ideas.

Architecture ![]() UI/UX Design

UI/UX Design ![]() Development

Development

![]() Architecture

Architecture

![]() UI/UX Design

UI/UX Design

![]() Development

Development

Leading Companies

Product Development

Film Production

Film Production

Mastery in visual storytelling

Fulfill your business’ video needs with a top-notch film production unit, bringing your brand the much-deserved spotlight from both local and global arena.

Brand Films ![]() Digital Advertisements

Digital Advertisements ![]() Animated Explainer Videos

Animated Explainer Videos

![]() Brand Films

Brand Films

![]() Digital Advertisements

Digital Advertisements

![]() Animated Explainer Videos

Animated Explainer Videos

Leading Companies

Brands who love us

Clientele